Category

WELDING AGENTS

Best Weld

A top quality and efficiency anti-spatter product. Eliminates the adhesion of spatter on the welded surface by more than 90% The formulation contains corrosion inhibitors.

Anti-stick liquid to prevent spatters from sticking during welding.

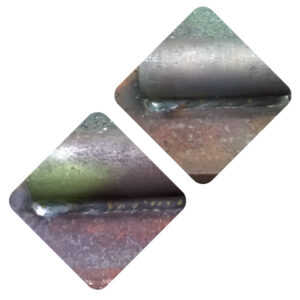

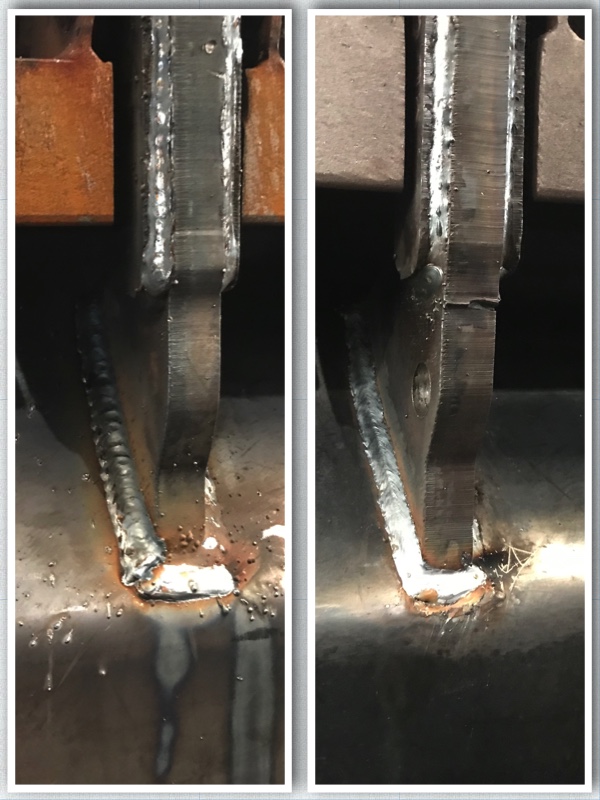

Our anti-spatter preparation is highly effective during welding (over 90% removal of spatters, and spatters that remain on the surface are mostly removed after wiping with a glove).

In addition, a very important advantage of our product is the very easy removal of the preparation itself after welding. As a result, the surface can be painted or even galvanized after using the product without any problems.

All these theses were proven and included in the report prepared by the Welding Institute in Gliwice, where a number of tests were carried out (x-ray, macrostructure, tearing) and the result of the effectiveness, the absence of negative effects on the weld and the absence of negative effects of the preparation on the galvanizing process, was very positive.

Our formulation is odourless, silicone-free and oil-free, and therefore very easy to remove after the welding process. The best option would be to use our BEST MAX degreaser to degrease the surface – this is a very high-quality and effective degreaser used for degreasing before painting, as well as for cleaning machines, equipment, floors, etc.

The BEST WELD anti-spatter preparation leaves the surface dry after use, which is why it works so well during the subsequent stages of production, such as painting or galvanizing.

Directions for use:

Water-based formulation.

1:1 – stainless steel

(1 litre of formulation: 1 litre of water)

from 1:1 to 1:2 – 1:3 – black steel

(dilution depends on several factors: welding parameters, wire, etc.)

WARNING: Check the dilution experimentally!

Product Benefits:

- non-flammable

- highly efficient (definitely more efficient than e.g. spray preparations)

- does not emit volatile substances hazardous to health during welding

- does not contain oil compounds (like the vast majority of spray preparations), so there are no objections to using it on materials that are subsequently painted or galvanised.

- no spattering saves time – increased efficiency. More efficiency means more profits for your business!

- economical: Best Weld is even 4-5 times cheaper than spray preparations! In addition, time saving due to the lack of spattering and the possibility of galvanizing after using our preparation

Welding chemicals – Efficient anti-spatter fluid

Efficiency is a measurable benefit for the user, but the greatest benefit is the time saved, because the very high efficiency of our anti-spatter means no need to clean the material from spatters, and neither the employee likes it (it is better to weld effectively without the need for cleaning – comfort of work) but also for the staff management, because it is definitely higher production efficiency. This is a very important aspect in the era of shortage of experienced welders. BEST WELD anti-spatter fluid “forgives” and “corrects” spatter errors that occur among young, inexperienced welders. It also allows you to eliminate spatter when the welder uses a low-grade welding wire.

Unbeatable quality

To sum up: the preparation beats other water-based preparations, and it is best seen with welding parameters favoring the formation of spatters, or in corners, hard-to-reach places, where spatters are the most and where they are most difficult to remove (various types of trusses, ribs, etc. etc.).

Economical and effective

BEST WELD industrial anti-spatter liquid is also economical.

Compared to any, even the cheapest spray preparation, it will be 2-3 times cheaper.